EN

/

CN

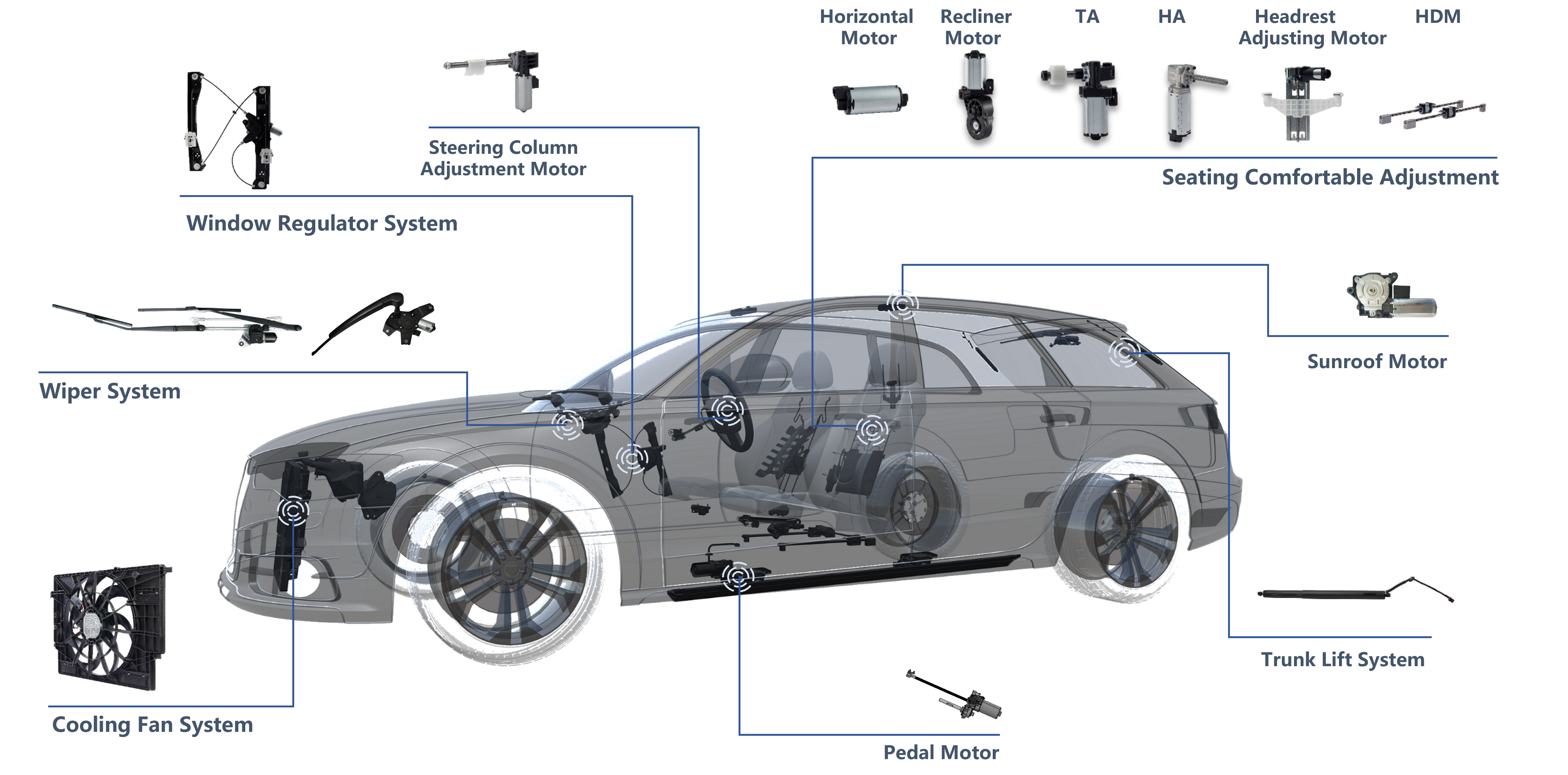

Height Adjuster Motor

Tilt Adjuster Motor

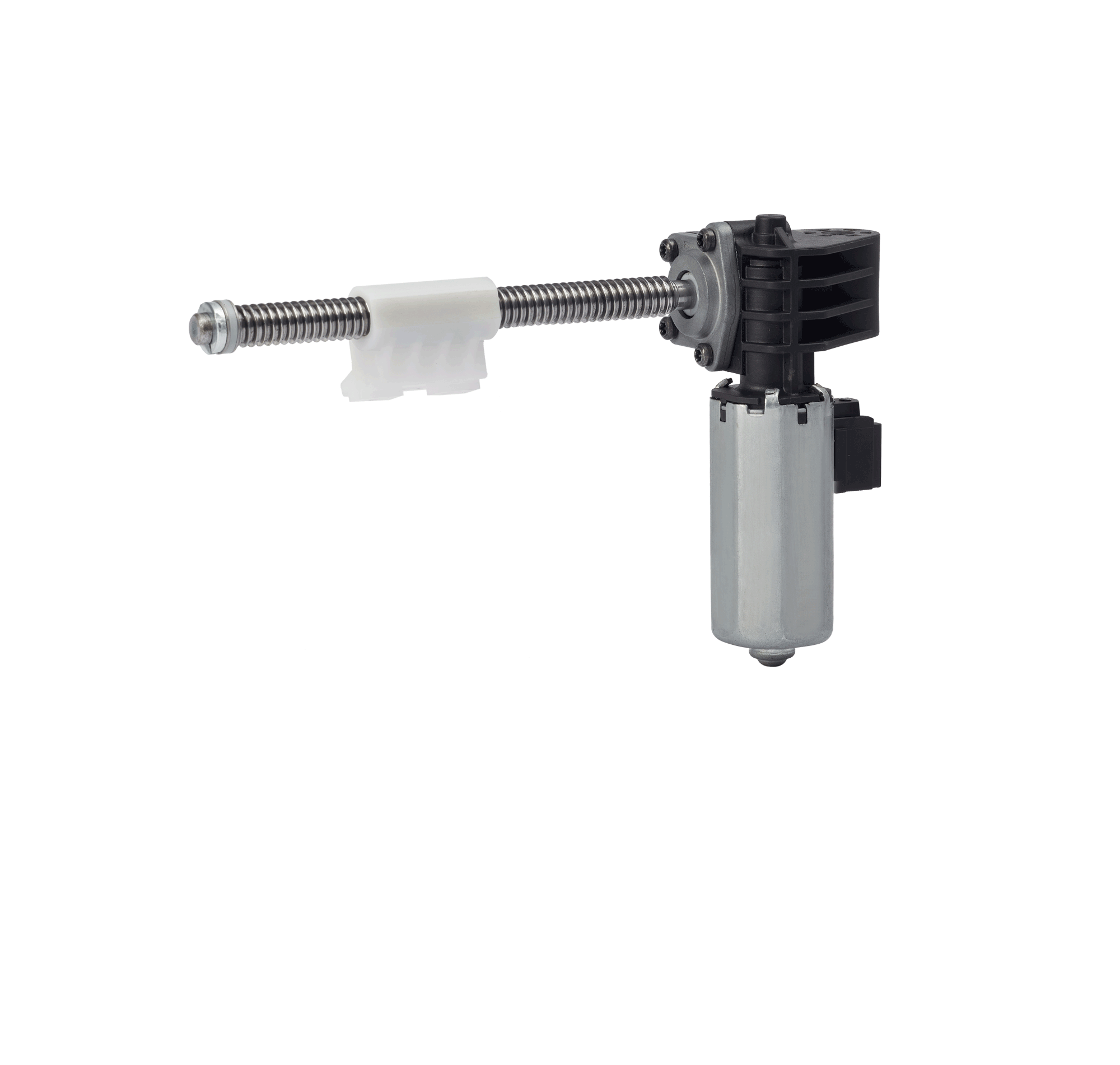

Horizontal Motor

Recliner Motor

Cushion Length Adjuster Motor

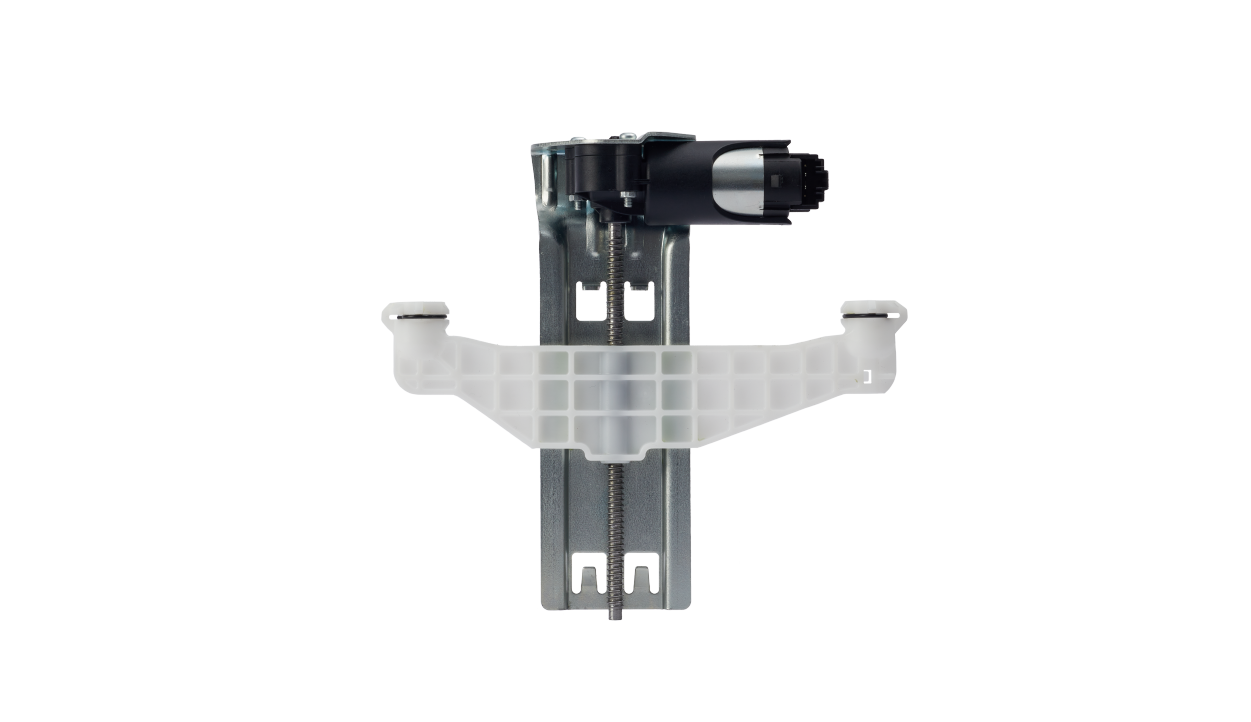

Headrest Motor Systems

HDM

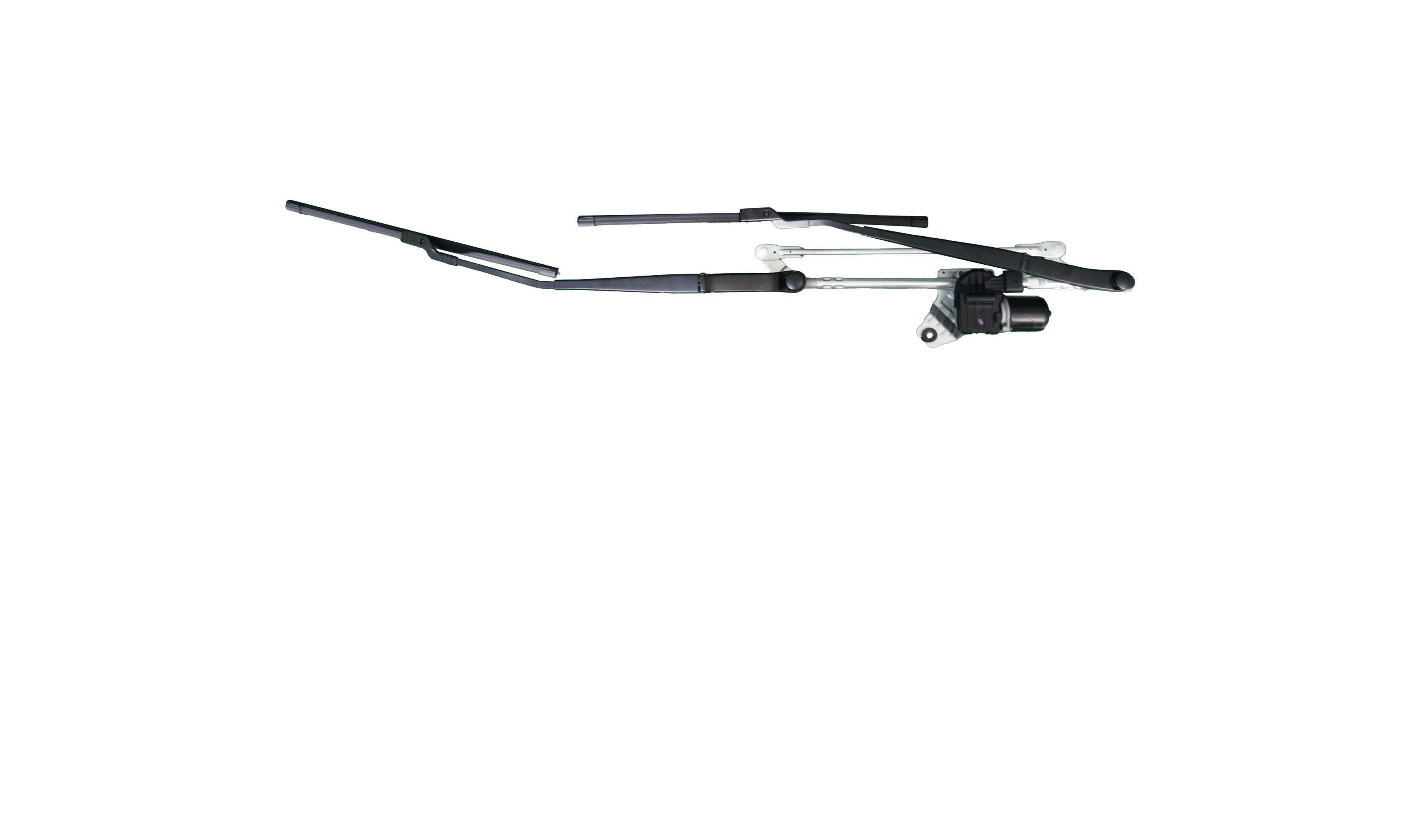

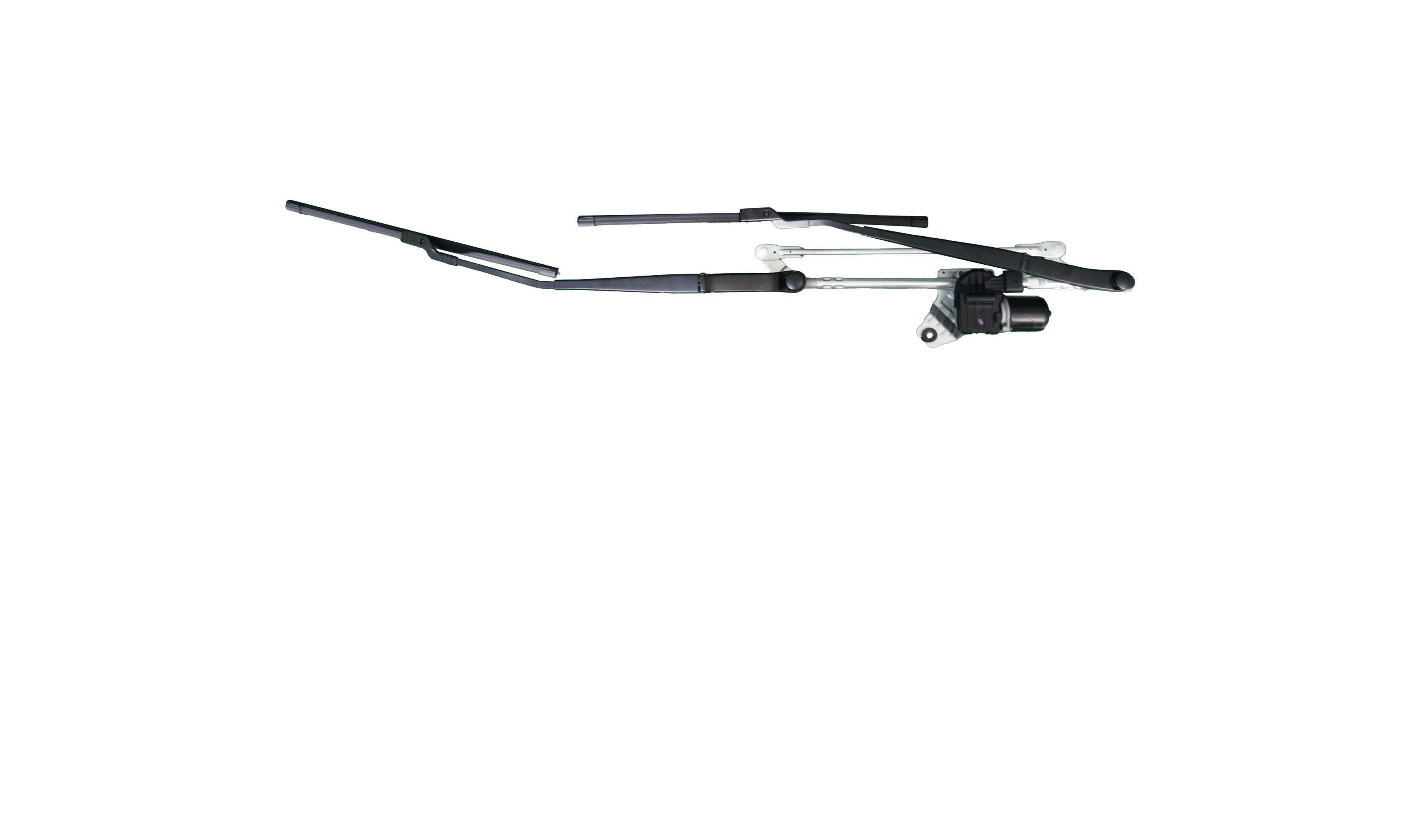

Conventional Front Wiper Sys.

Smart Motor Front Wiper Sys.

Rear Wiper Sys.

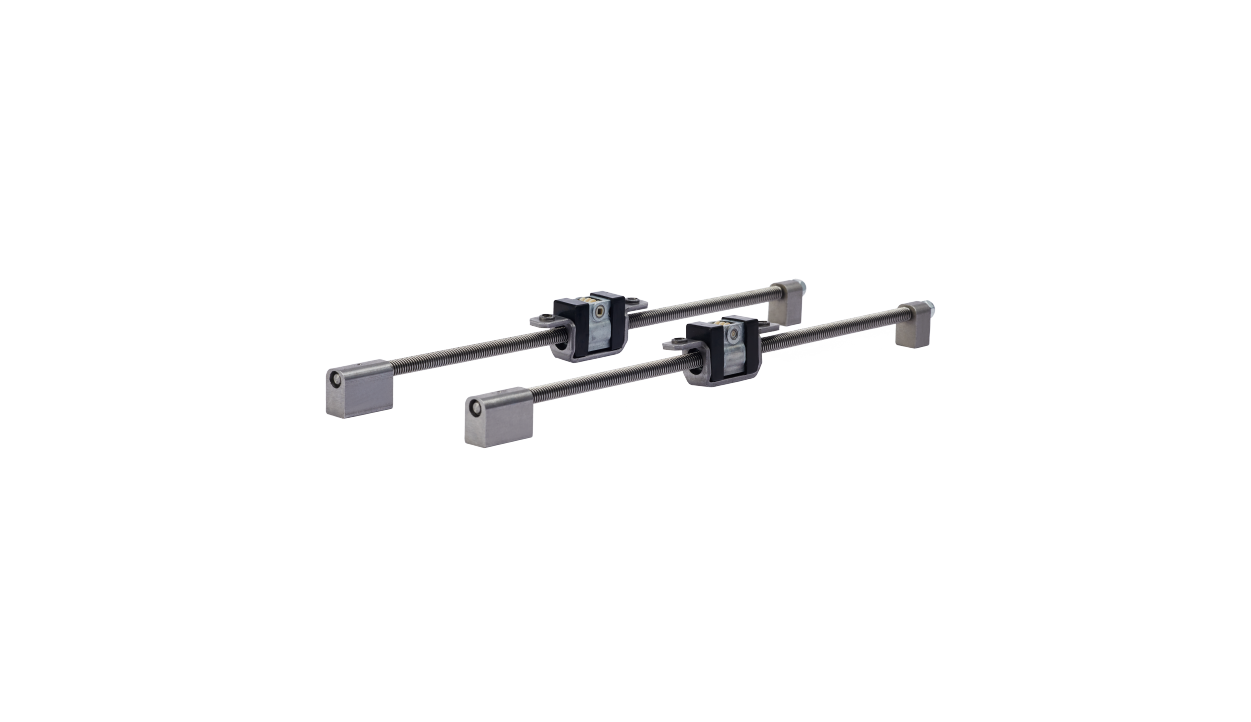

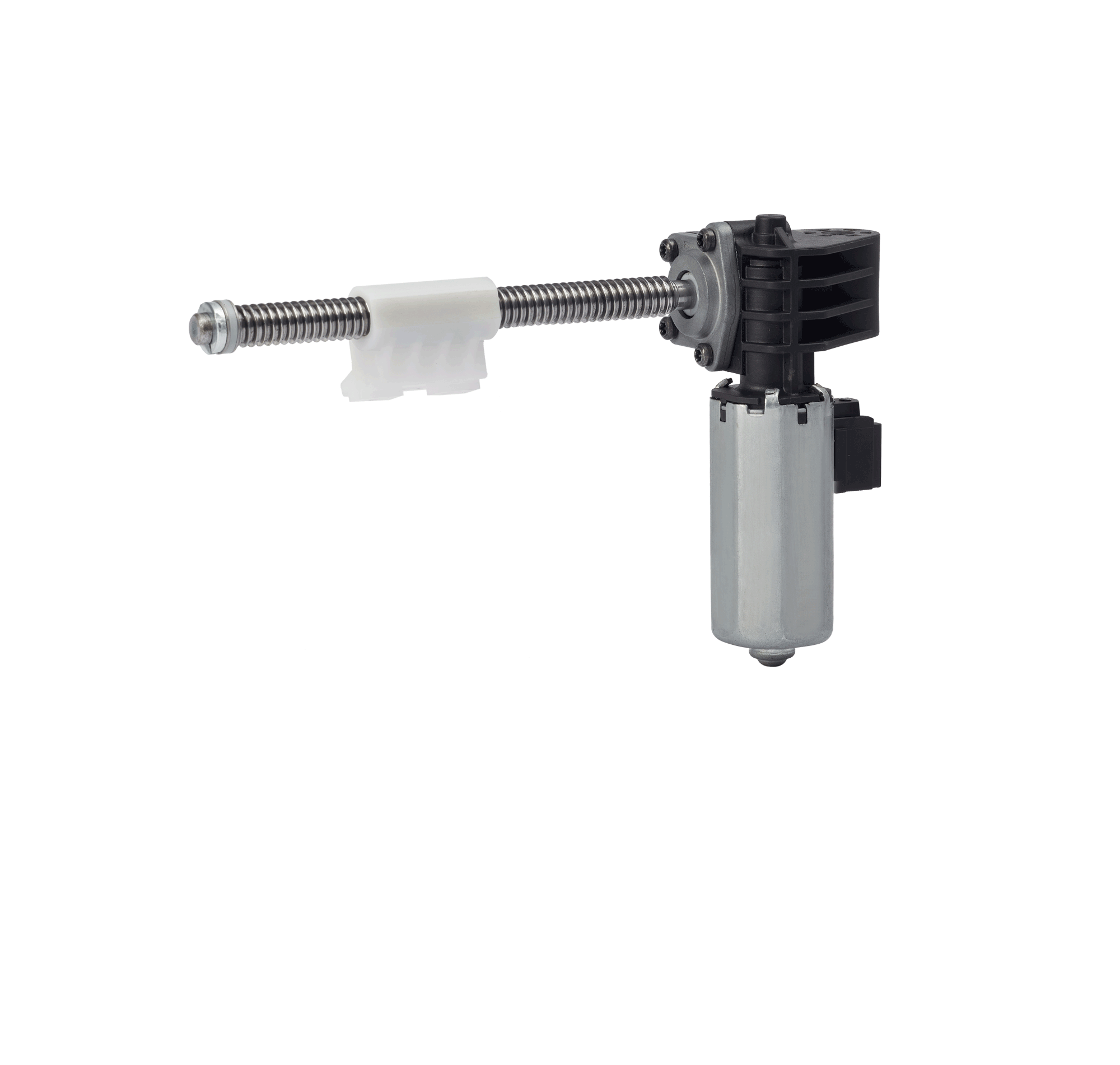

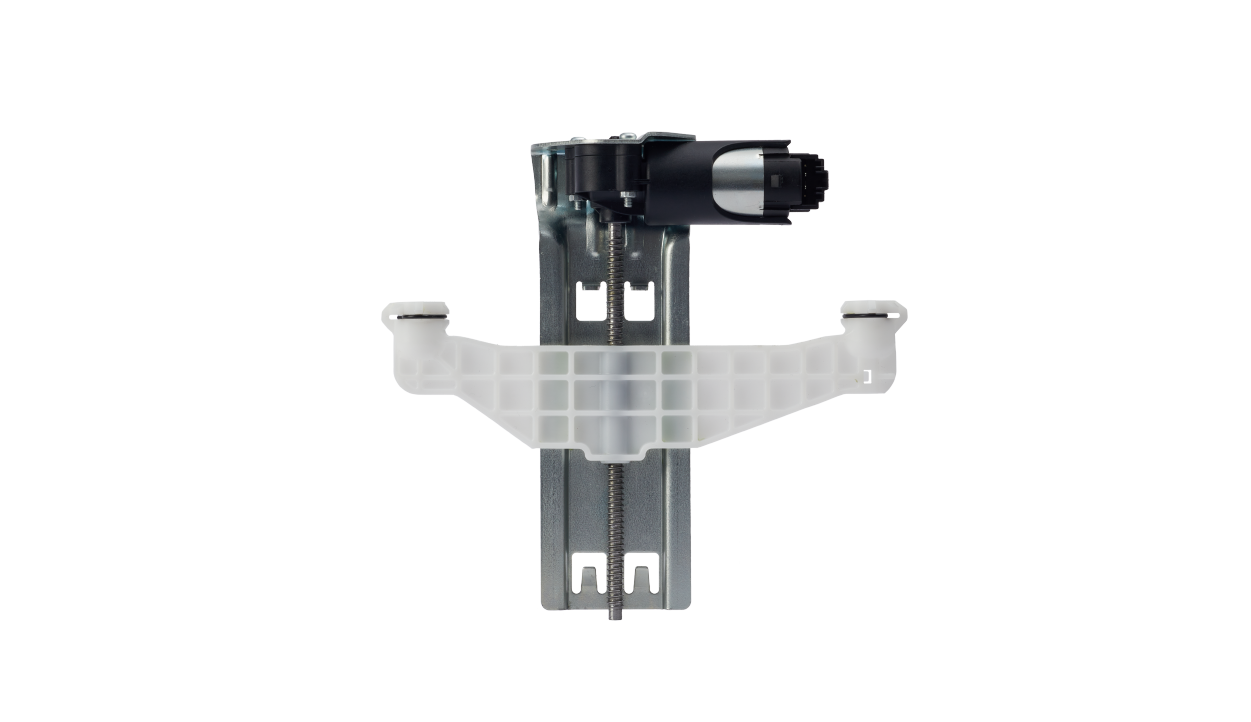

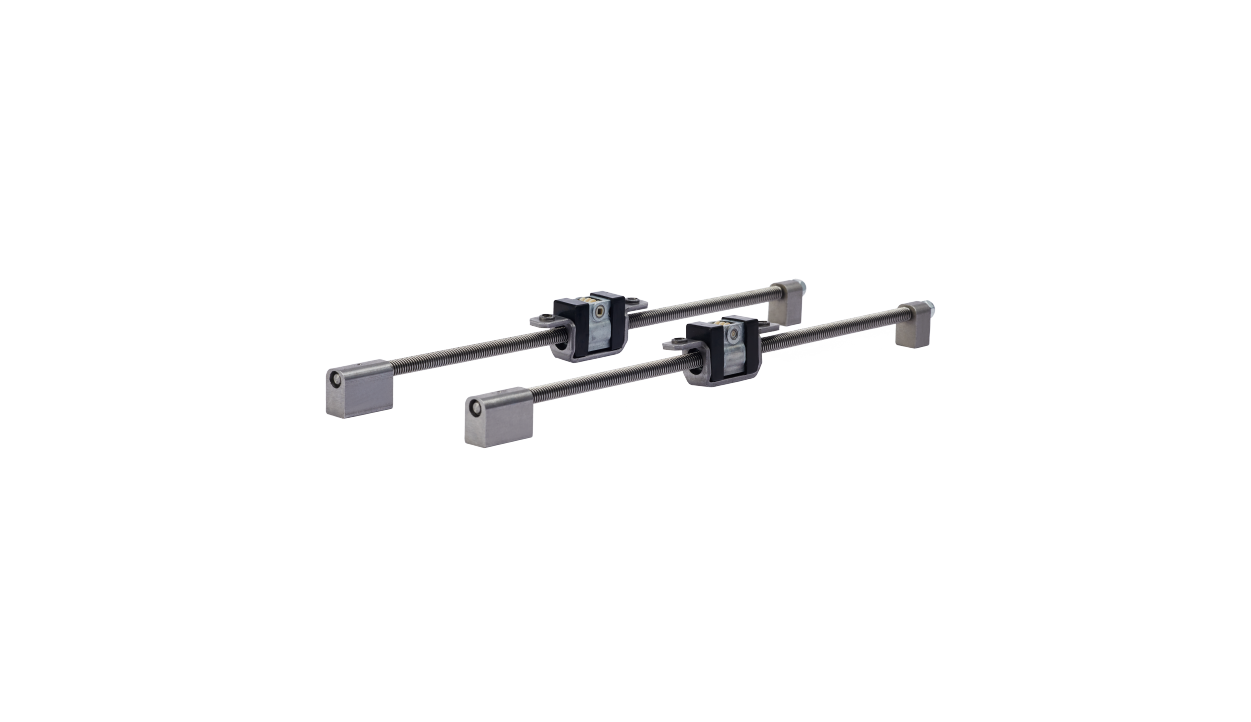

PLG Spindle

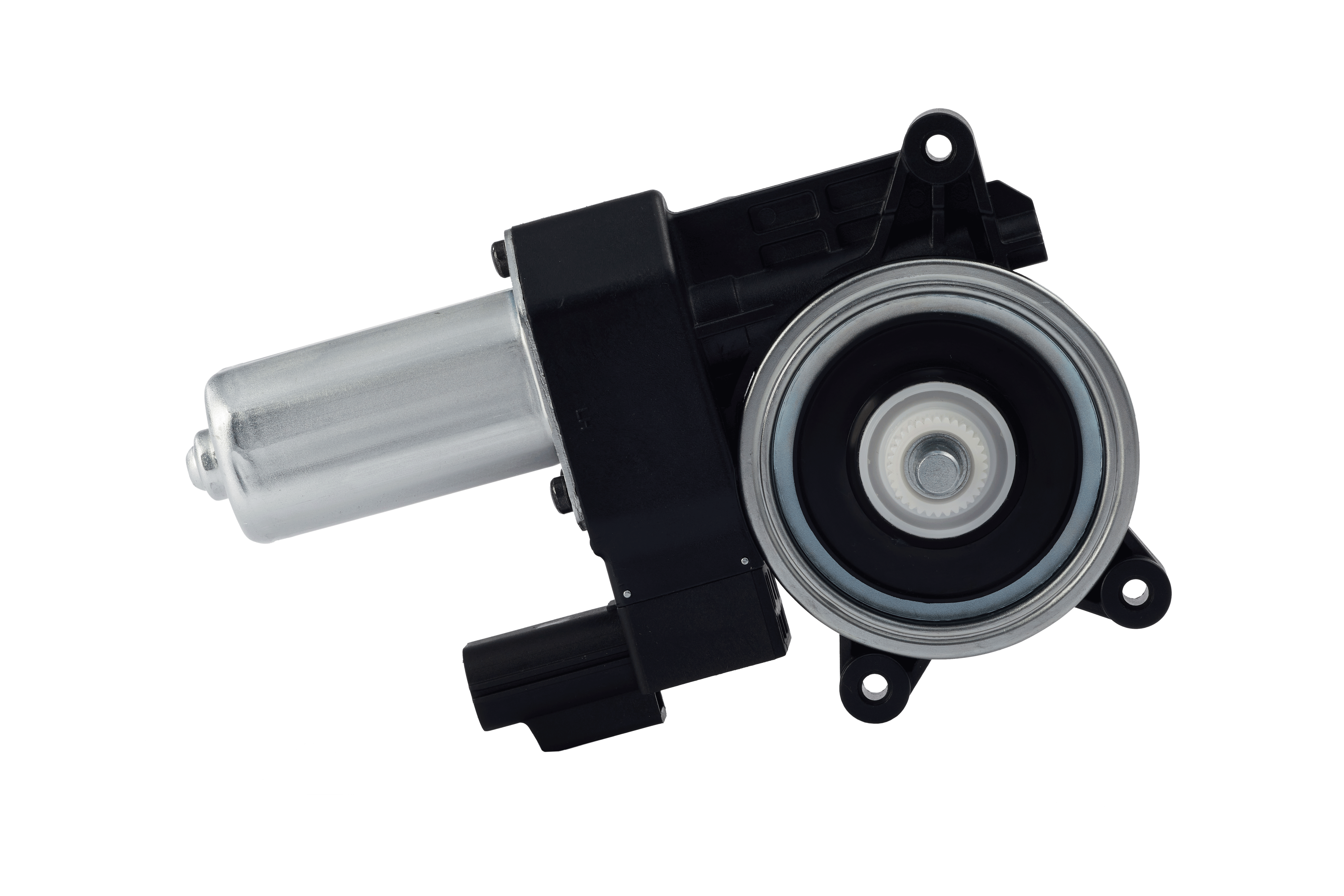

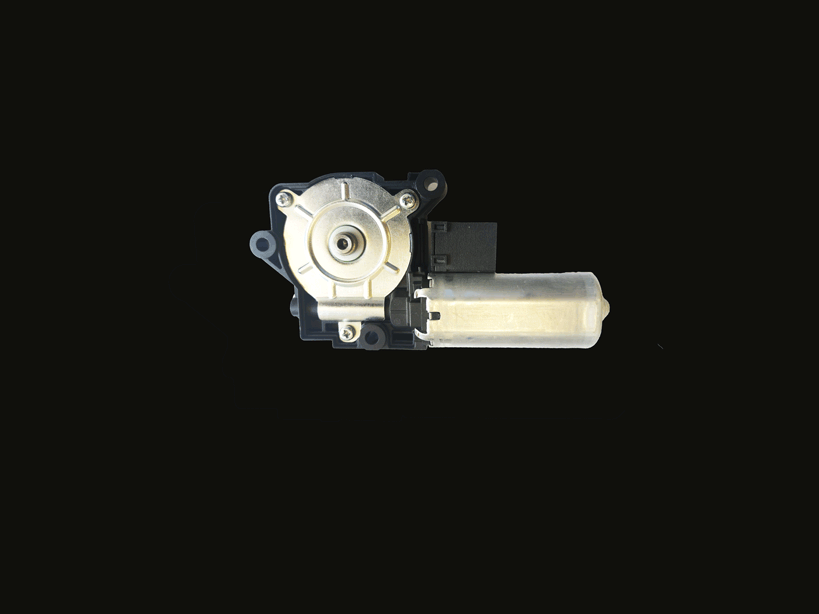

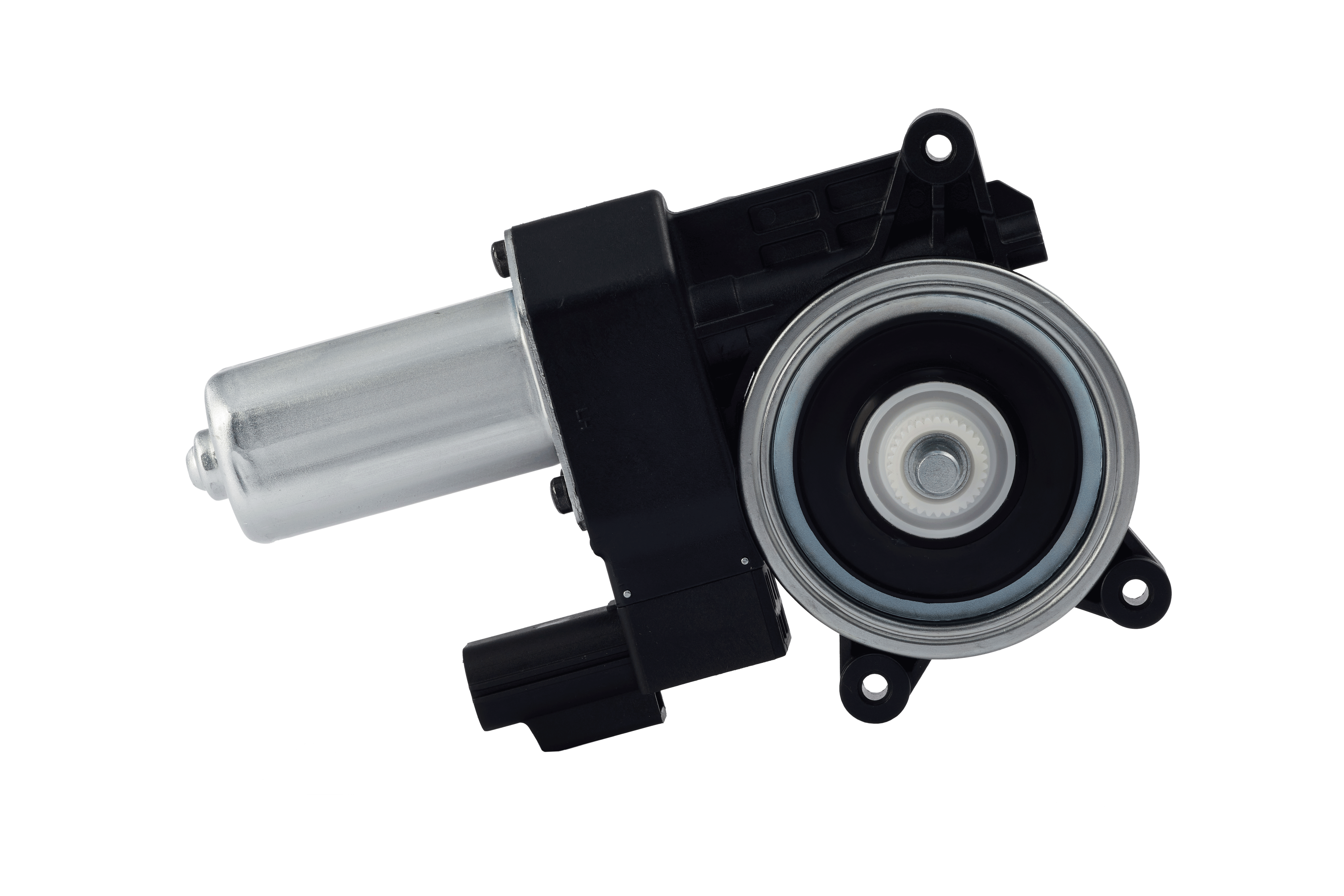

Window Regulator Motor

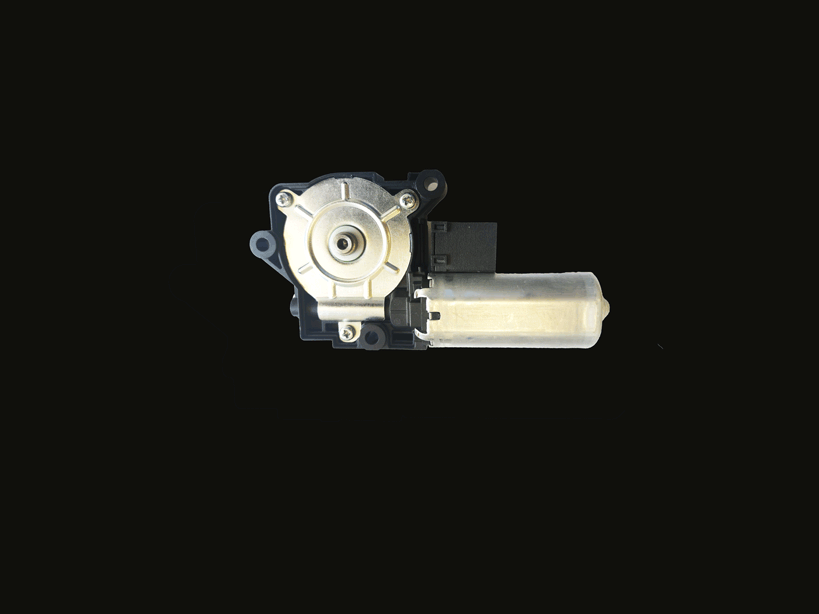

Sunroof Motor

Horizontal Adjustment Motor

Vertical Adjustment Motor

350W BLDC Motor Fan

450W BLDC Motor Fan

650W DC Motor Fan

1000W BLDC Motor Fan

Allows the user to adjust the height of the seat. These motors have an optional memory function to automatically return the seat to a preset position for each individual driver.

Allows the user to tilt the angle of the seat to a preferred position. These motors have an optional memory function to automatically return the seat to a preset position for each individual driver.

Allows user to move the seat backward or forward to adjust the driving position. These motors have an optional memory function to automatically return the seat to a preset position for each individual driver

Allows the user to adjust the seatback to recline to the comfortable position for the individual user.

These motors have an optional memory function to automatically return the seat to a preset position for each individual driver.

Allows for adjusting the length of the cushion. The front part of the seat will move forward or backward to allow the user to adjust for a comfortable support for the legs. These motors have an optional memory function to automatically return the seat to

Allows the user to regulate the position of the headrest up or down. These motors have an optional memory function to automatically return the seat to a preset position for each individual driver.

1. Technical maturity

2. Stable quality

3. Compact size

4. Lighter weight

5. Low noise

1. Technical maturity

2. Stable quality

3. Compact size

4. Lighter weight

5. EMC3-5

6. High waterproof level

1. Appearance enhancement

2. Wipe angle stability

3. High polished rate

4. Lower noise

5. Stepless speed regulation

6. Save space

7. Operation convenience

8. Snow load protection

9.Energy control

1. Technical maturity

2. Stable quality

3. Compact size

4. Lighter weight

5. EMC3-5

6. High waterproof level

1. Smart clip prevention

2. Height adjustment

3. Warning prompt

4. High safety factor

4. Prevent abuse

5. Platform design

1. Stable quality

2. Strong carrying capacity

3. Low noise

4. High waterproof level

1. Technical maturity

2. Stable quality

3. Compact size

4. Low noise

5. Lighter weight

1. Technical maturity

2. Stable quality

3. Compact size

4. Low noise

5. Lighter weight

1. Technical maturity

2. Stable quality

3. Compact size

4. Low noise

5. Lighter weight

1. Stable quality

2. High torque low speed

3. Low noise

1. Stable quality

2. High torque low speed

3. Low noise

1. Stable quality

2. High torque low speed

3. Low noise

1. Stable quality

2. High torque low speed

3. Low noise